Service, consulting, automation

After close to 35 years in the automation business we offer you as our customer experience with both depth and width, from various types of automation applications.

PLC SOFTWARE

We work mainly with CoDeSys based systems, i.e. Beckhoff TwinCAT. Close to 20 years of experience with those systems gives us great knowledge and quality. Of course vi also work with other system, not least Siemens (TIA Portal).

HMI Systems

Over the years we have built up a knowledge base around different HMI and SCADA systems, for instance Indusoft and CiTect. We can also commit to develop HMI systems in .NET.

Servo systems

In conjunction with PLC programming we have worked with different types of servo aplications, where servo drives from Bosch-Rexroth, Beckhoff, Omron, Mitsubishi and others have been used.

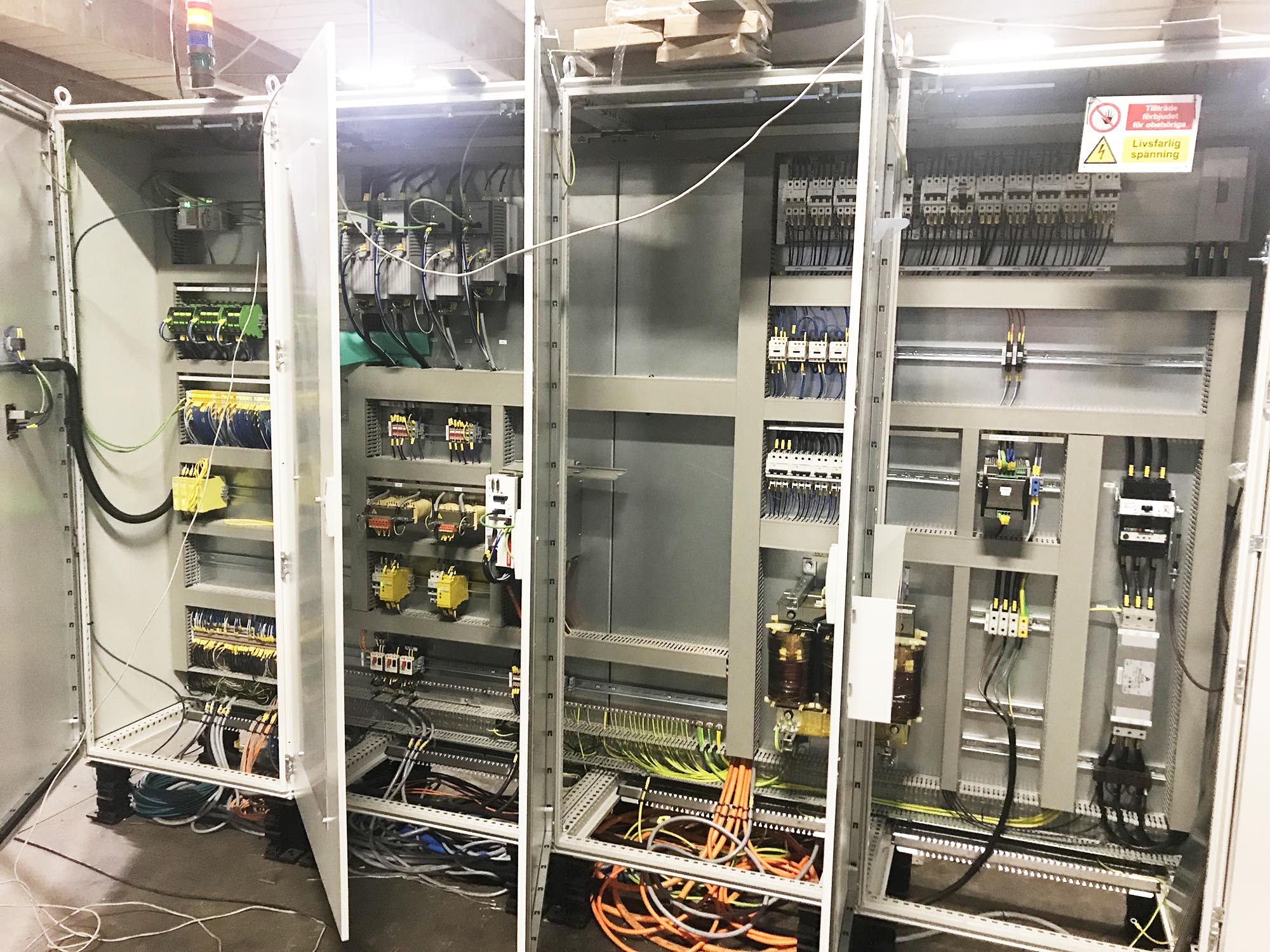

ElECTRICAL DESIGN

We take responsibility for the whole process, from specifications up to complete designs, both for new applications as well as retrofits. At the moment we work mainly with ElproCAD, but can also create design and documentation using Eplan P8.

STARTUP AND COMMISSIONING

A machine or production line is not ready just because it is assembled in the workshop. Now the commissioning and optimisation takes place, both in the workshop as well as at the end customer. We work closely together with you as our customer to achieve the optimum result.

Service

We also accept service missions, retrofits and upgrades of machines and lines. With our broad contact network, we can help you with everything from a new control system up to mechanical modifications of your equipment.

broad experience

Today you will find our customers in several areas, yet most of them work with special machines, processing machines and production lines of all kind.

You will find conveyor systems, simple and complex processing machines, packing machines and turn-key production lines in our scope.

Even in the process industry you will find HH SeConAut AB customers, especially in petroleum handling and biofuel, but also in the food industry.

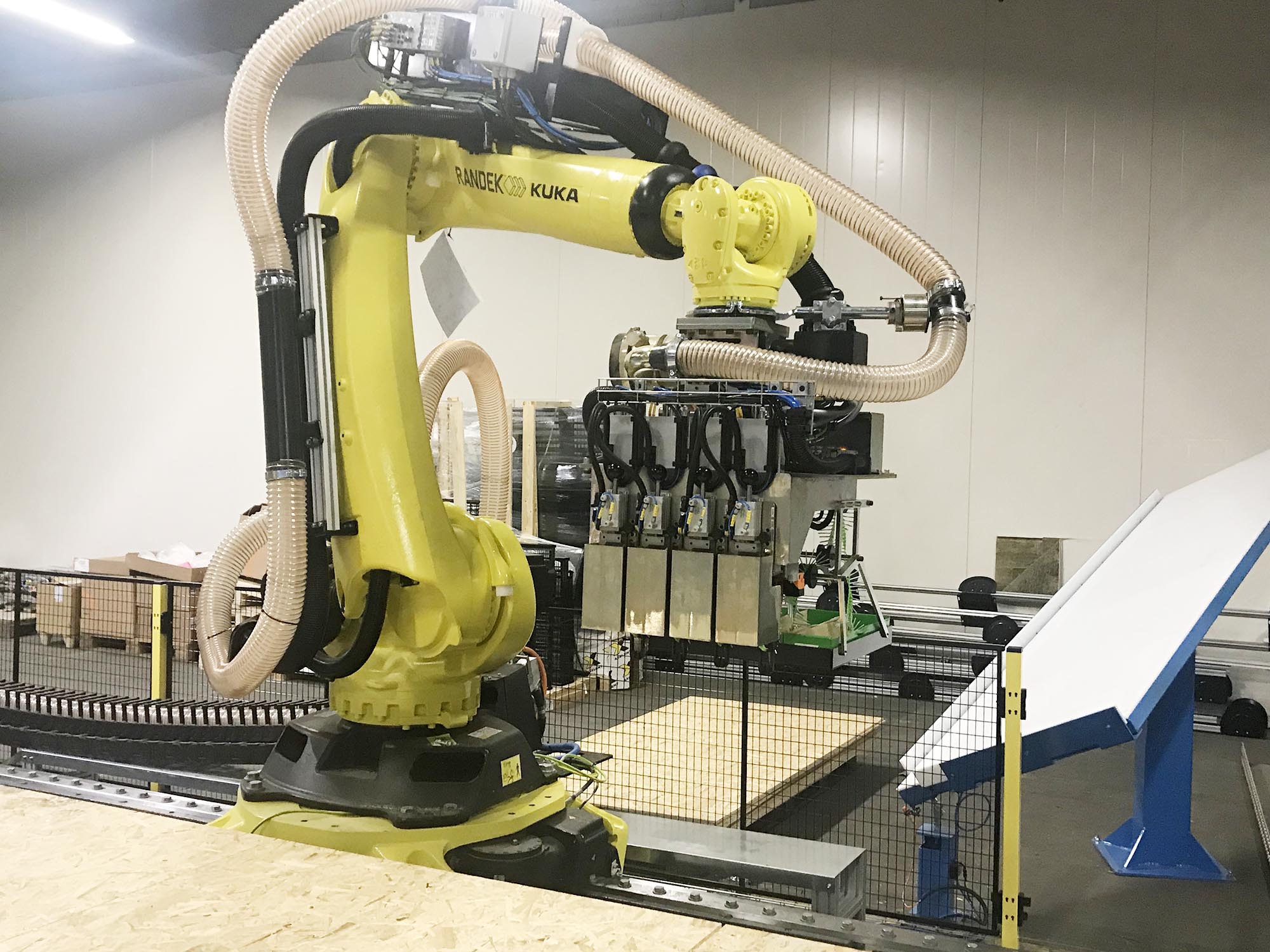

APR Automation Robot line, usa 2018

Fully automated production line for wall panels. In the line, wall frame work is assembled based on CAD data from customer. Robots place and fasten boards, cut out door and window openings etc.

Randek wall line, canada 2016

Partly automated production line for wall panels. In the line, wall frame work is assembled based on CAD data from customer. This line has been moved from a previous customer in Denmark, modified and commissioned in Canada.

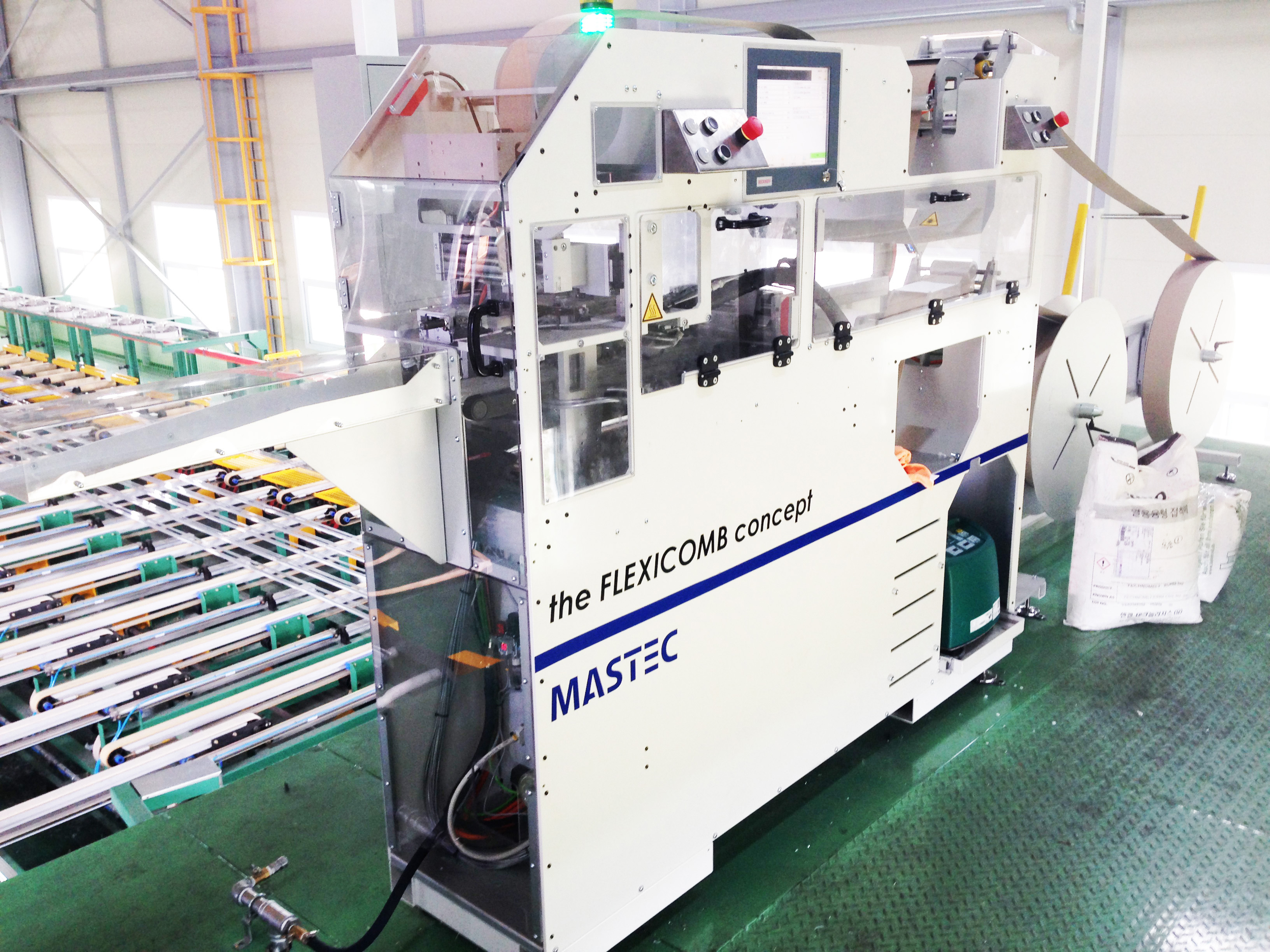

Mastec flexipac Europe and Asia, 2015-2017

This machine produces packing materials used for instance in the aluminium industry to protect parts packed in pallets or similar. Customer can program shape of the packing aid to fit their specific products.

obducat “sindre”, usa 2014

Production equipment for medical components to customer in the US. The production process is based on Nano technology and demands accurate control and regulation of pressure and temperature in the different process stages.

boge robot retrofit, 2016

Exchange of existing control system for a SCARA robot at customer in Germany. The new control system is based on Beckhoff TwinCAT 3 with additional SCARA kinematics.

Schur packing conveyor system, 2018

Conveyor system feeding a sheet printing press with raw material. High demands in terms of availability, fast pallet changes and high precision in positioning material for printing press.

Partners